MANUFACTURING PROCESS

Standards of Production

Partner success is key to CorrLoc’s vision to have a national manufacturing footprint. Partner support will always be a focus of the CorrLoc Licensee program. SOPs are designed to lead partners step-by-step to successful manufacturing.

Our SOPs provide a blueprint for success for our partners. They include an overview of the machinery and production process. Our SOPs demonstrate that there is repeatability in the manufacturing process. The high standards set in our SOPs ensure an excellent product performance when followed exactly.

Overview of the CorrLoc Rail Manufacturing Process

- Easy to replicate

- Systematized

- Consistent Results

- Fast Changeover Rate

- Product Design Flexibility

- Proven Track Record of Success

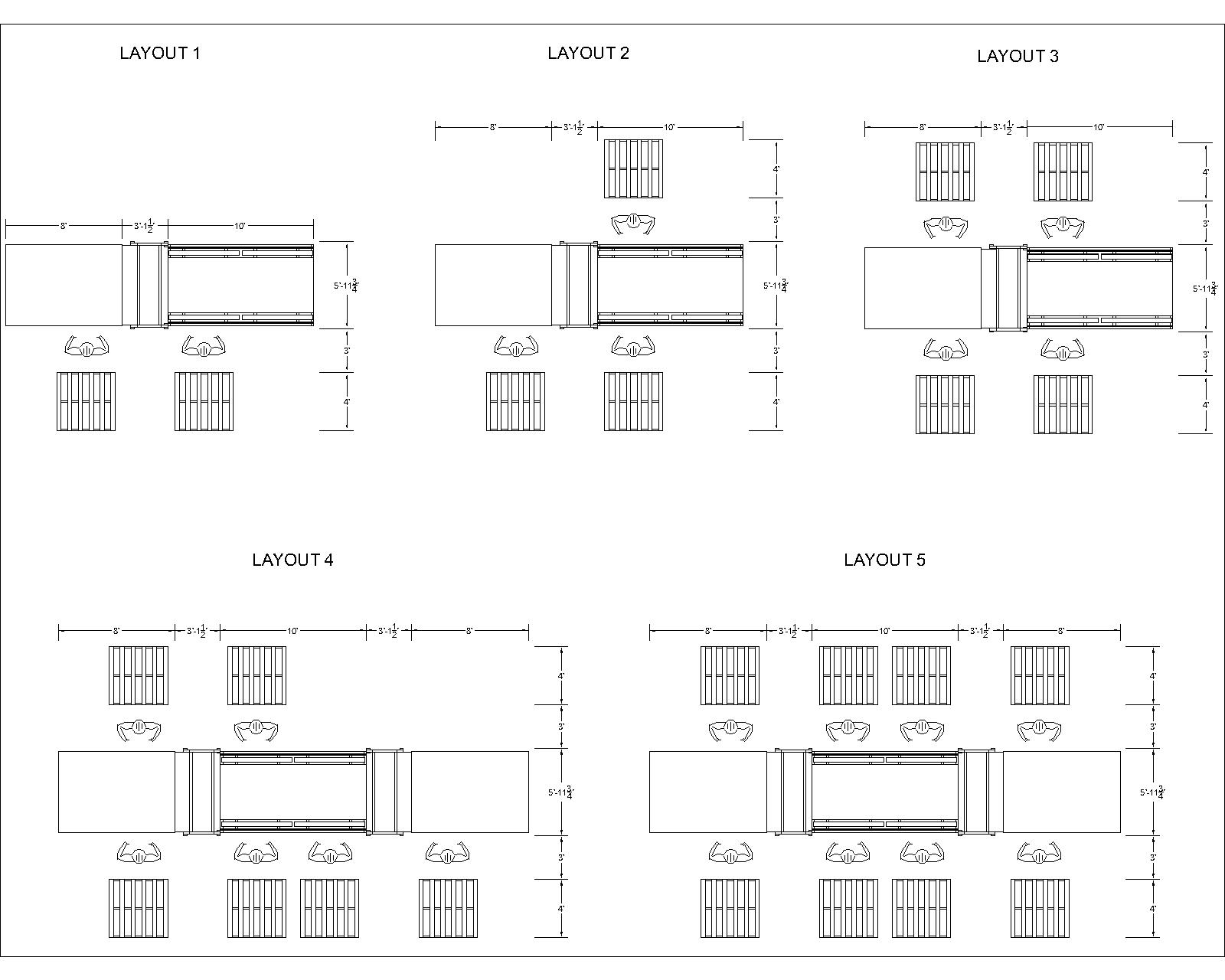

PRODUCTION LINE LAYOUT

CorrLoc has established the best practice for laying out the necessary equipment in an efficient way. As a CLOUT Partner, you will have detailed plans for your production line layout.

BREAK PATTERN

The corrugate sheet is scored in a break pattern that makes folding for glue preparation simple. This step is detailed in our SOP document given to all CLOUT Partners.

GLUE

Our Adhesive Applicator makes evenly gluing the corrugate easy.

FOLD & CLAMP

After glue is applied, use the Clamp Table to fold the rail into shape. Then place the folded rail into the clamp to finish.